The MJ6233A horizontal panel saw, also called beam saw is a powerful and precise way to cut panels for a variety of woodworking projects.

This cutting-edge horizontal panel saw takes your craftsmanship to a new level.

share to:

The MJ6233A horizontal panel saw, also called beam saw is a powerful and precise way to cut panels for a variety of woodworking projects.

This cutting-edge horizontal panel saw takes your craftsmanship to a new level.

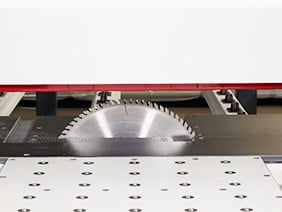

Zicar horizontal panel saw is an incredibly powerful and efficient machine designed to optimize your production time. The user-friendly automation allows for quick and easy loading and unloading of materials with the optional air floatation on the machine’s in-feed and out-feed tables. Furthermore, a convenient one-button operation allows for effortless cuts and adjustments to the speed of the saw blade. The pneumatic pressure bar ensures that stacked panels are secured swiftly across the entire kerf line delivering a clean cut each time. If you want to dramatically improve your manual operations, Zicar 6233A Series is your ideal companion.

If looking for simple operate manual adjustment version, click the link of MJ6233B series.

Model |

MJ6233B |

MJ6233A |

| Length of cutting | 3200mm | 3200mm |

| Height of cutting | 100mm | 100mm |

| Width of cutting | 3300mm | 3300mm |

| Main saw speed | 4800r/min | 4800r/min |

Positioning method |

Manual |

Automatic |

| Sawing precision | ±0.2mm | ±0.2mm |

| Main saw motor power | 16.5kw | 16.5kw |

| Main saw blade diameter | 360mm*80mm | 400mm*80mm |

| Scoring saw blade diameter | 180mm*55mm | 180mm*55mm |

| Traction motor power (rack drive) | 2.0kw Servo motor | 2.0kw/1.8kw Servo motor |

| Scoring saw motor power | 2.2kw | 2.2kw |

| Gripper servo motor power | – | 2.0kw/1.8kw Servo motor |

| Air-floating table fan motor power | 4kw | 4kw |

| Sawing speed | 0-100m/min, Frequency | |

| Air pressure | 0.6-0.7Mpa | |

| Total power | 24kw | 27kw |

| Weight | 3800kg | 4900kg |

| Overall size | 5900*3500*1900mm | 5900*5800*1900mm |

1.The self-explanatory graphical user interface ensures that your employees can start operating the machine quickly and properly without any major training.

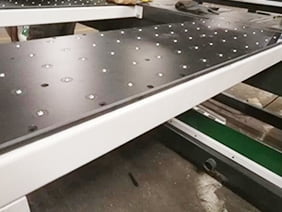

2.High functionality – perfect ergonomics can meets the highest demands in terms of its technology and equipment. Air cushions for the machine table protect the workpiece during handling. A powerful fan provide a large area air cushion,which allows heavy stacks of panels to be moved easily.

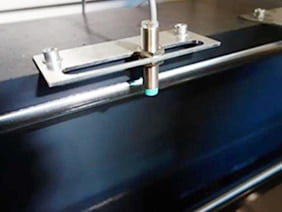

3.Stable, welded construction with precision, hardened linear guides ensure precise, smooth running. Direct rack-and-pinion drive and proximity-type sensor for absolute dimensions guarantee maximum positioning accuracy.

4.Perfect hold – the classic workpiece clamps All clamps are mounted floating and can compensate for irregularities in panels/stacks by means of a linear guide.

5.Perfect cutting results – New cutting direction

Please fill in the form with your details and we will get back to you as soon as possible.

Frequently Asked Question

What kind of machine you offer?

How to choose suitable machine?

How long is the machine leading time?

Oversea Service (Technical Assistance)

Could you ship machines to my country? If possible, could you make DTD?

How long is guarantee?

Where and how long can we get the replacement parts?

Payment Terms

Could you make the machine according my own requirements?