CNC Six-Sided Drilling Machine

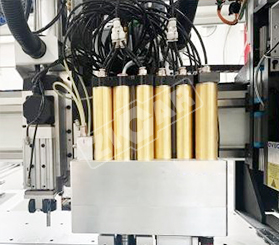

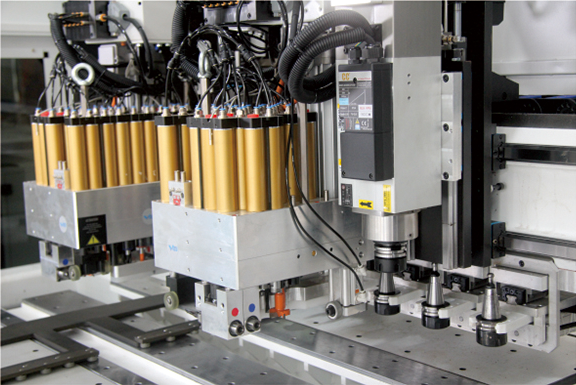

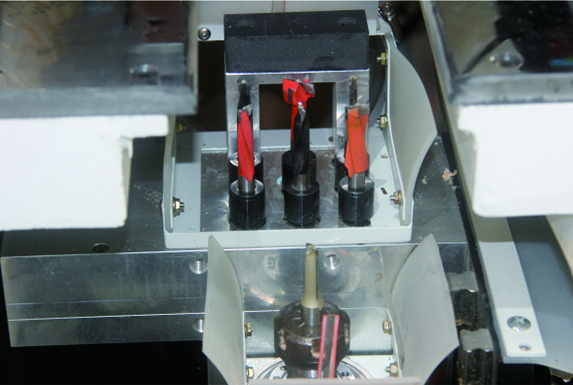

Drilling unit + ATC spindle+5 pieces tool changer

share to:

CNC Six-Sided Drilling Machine

Drilling unit + ATC spindle+5 pieces tool changer

Applicable industry: Custom furniture,panel furniture,Cabinet wardrobe,office furniture.

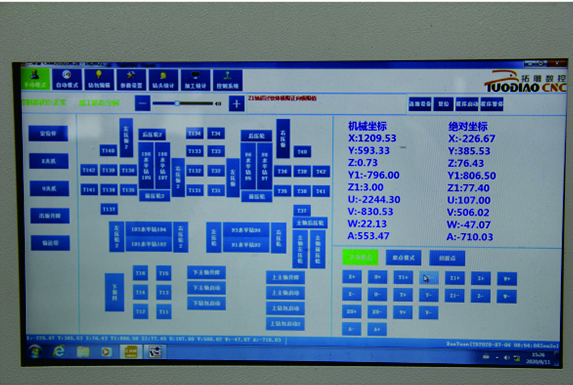

1. Drilling on six sides at one time,slotting on the front and back sides

2. Three side spindle for easy side slotting

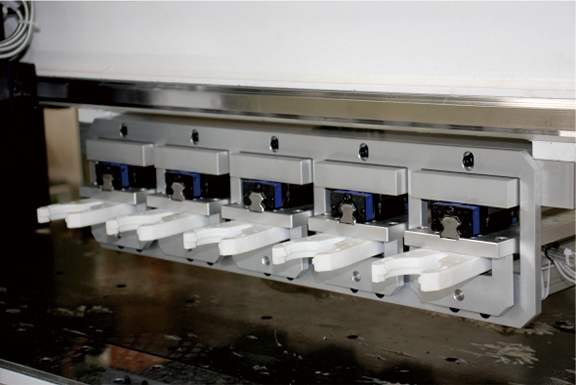

3. Minimum board support 35x70mm,online board supports 50x250mm,and can be produced in the whole order

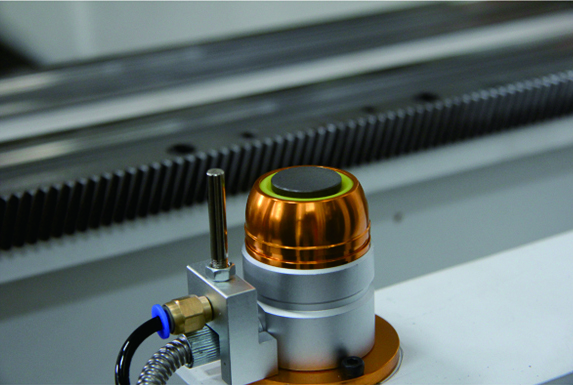

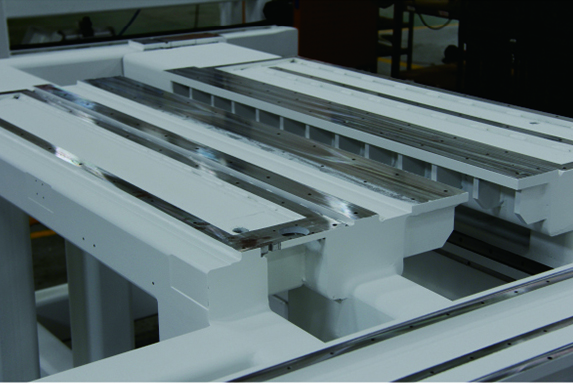

4. Workbench with air flotation holes,prevent damage from board surface

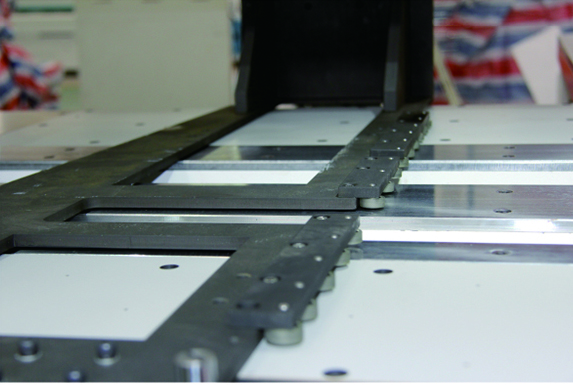

5. Y-axis long guide rail,double gripper,automatic side leaning to ensure stability

6. Compatible with various design software,support files like:XML,BAN,MPR.etc.

| 1 | Model | C6A |

| 2 | panellength | 70-2800mm |

| 3 | Panel width | 35-1200mm |

| 4 | Panel thickness | 12-50mm |

| 5 | Maximum speed | 130m/130m/80m/min |

| 6 | Top horiz drills | X:4pc+Y:4pc |

| 7 | Top verti drills | 12pc |

| 8 | Top Spindle power | 6kw ATC Spindle + 5 tools |

| 9 | Below verti drills | 6pc |

| 10 | Below Spindle power | 3.5KW |

| 11 | Driving system | EtherCAT AC Servo |

| 12 | Dust collector | 150mm*2 |

| 13 | Gas pressure | 20.6Mpa/m |

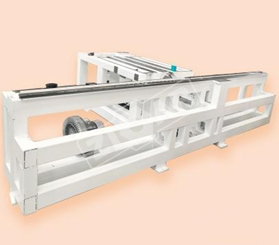

| 14 | Overall size | 4200*2600*2200mm |

| 15 | Net weight | About 3800kg |

| 16 | Working voltage | 380V 50/60HZ |

| 17 | Total power | About 22KW |

|

|

|

|

|

|

|

|

Please fill in the form with your details and we will get back to you as soon as possible.

Frequently Asked Question

What kind of machine you offer?

How to choose suitable machine?

How long is the machine leading time?

Oversea Service (Technical Assistance)

Could you ship machines to my country? If possible, could you make DTD?

How long is guarantee?

Where and how long can we get the replacement parts?

Payment Terms

Could you make the machine according my own requirements?