| Stability |

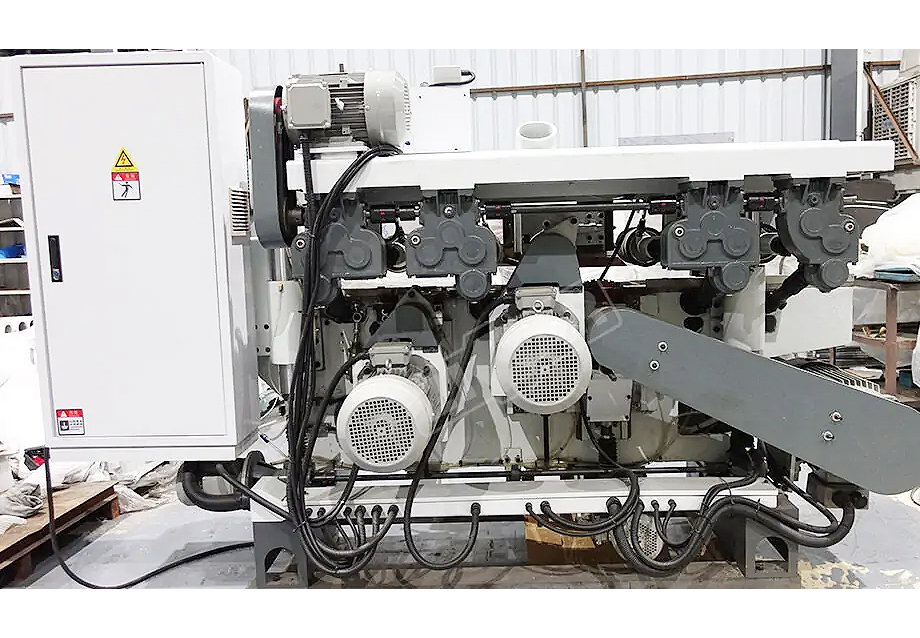

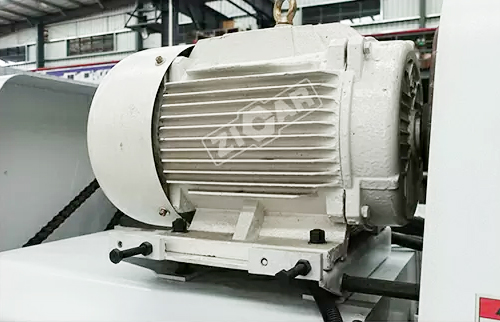

The bed is made of high-grade cast iron to ensure the stable performance of the whole machine. |

| Hard chrome plated work surface and durable |

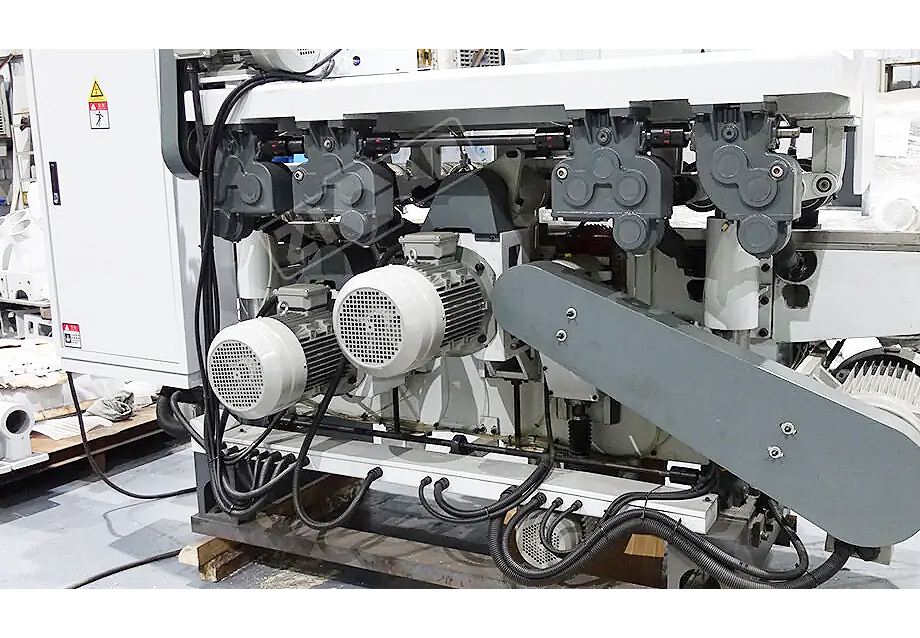

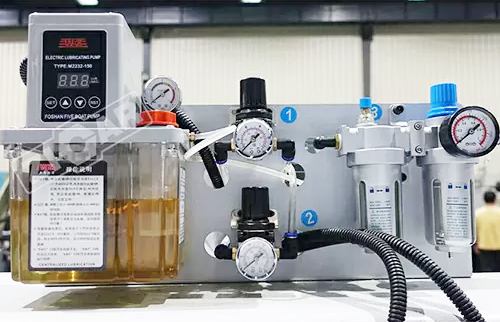

| Equipped with imported electrical components,high stability. |

| Convenience |

The new panel design is beautiful and convenient to handle, to adjust the speed. |

| Spindle adjustment is concentrated in the front for easy operation |

| Safety |

Completely sealed safe cover can avoid saw dust and isolate noise efficiently, also can protect workers |

| Processing effect |

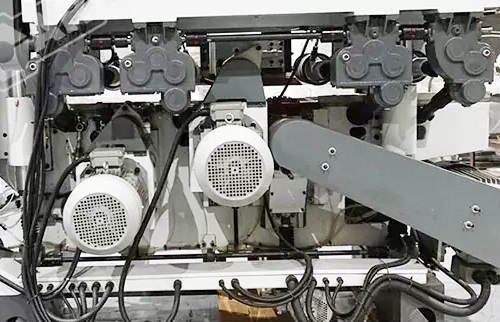

Each shaft is driven by indepent motor,cutting effect is very good. |

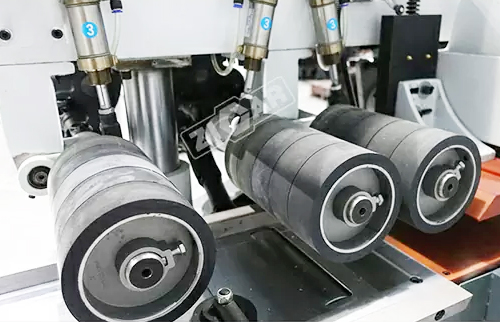

| Multiple sets of up and down active wheels improves the feeding efficiency. |

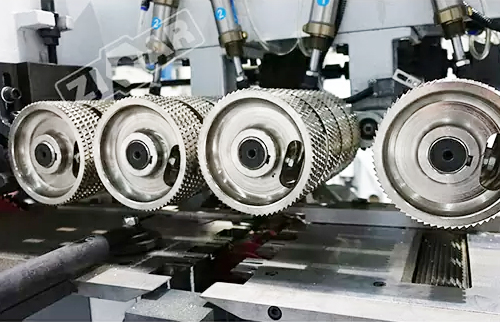

| Heavy duty design with good materia can keep high precision, high stability and high reliability. |

| Pneumatic compaction type feed wheel, which can adjust the compaction force in sections, which is conducive to the smooth feeding of different thickness wood |

| The lower worktable has 3 sets active feeding wheels and 1 set passive feeding system, upper worktable has 2 sets active feeding wheels, which make the feeding more smoother. |

| Magnetic grid sensor for thickness display, the accurancy is much higher than proximity sensor. |

The feeding system adopts pressure pin encryption structure,and narrow materials can be passed, and the scope of use is wider.

The feeding system adopts |

| Spiral cutterhead is for optional,it can provide fine planed surface without noise. |