Which edge banding machine should I buy ? How many functions? What price ? This is a question that most businesses that are intending to invest always need a detailed answer. Information about the edge banding machine for industrial wood is a lot, but it still does not satisfy the concerns of businesses. Hope today’s sharing will satisfy your interested businesses.

Application of edge banding machine for wood and industrial

As you know, wood edge gluing is an indispensable stage in the production of furniture from plywood. Edge gluing can protect your product against damage from termites or the surrounding environment. . Previously, the edge banding machine was not used much because it was considered an expensive machine that many facilities were afraid to invest in. Most are manual edge-gluing or semi-automatic gluing machine.

Nowadays, wood edge banding machines have become more popular and widely used, with many different types and prices. Information about the edge banding machine is too much, but none of them are detailed enough for you to fully understand the machine. That’s why today Zicar will share the secret for you to choose the right pvc edge banding machine for you.

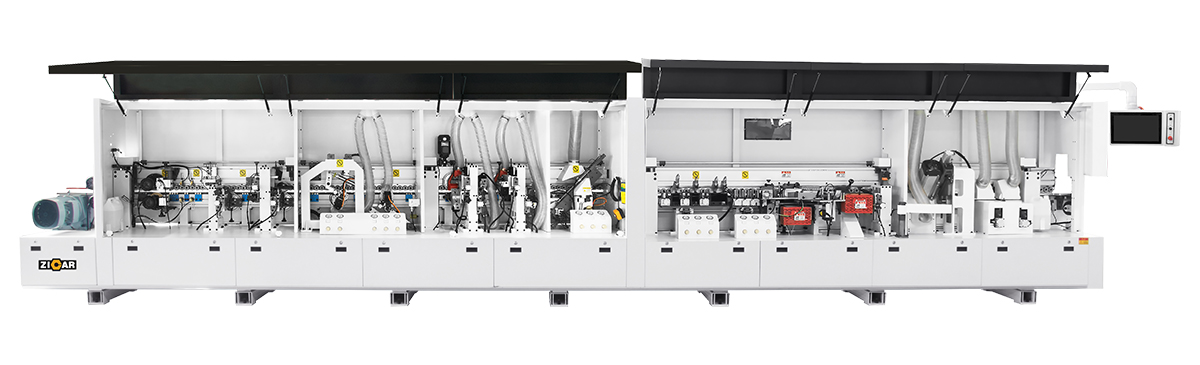

The most popular PVC Edge Banding Machine today

1. 5 function edge banding machine MF50G

The 5-function edge banding machine is equipped with a large-capacity motor system. With the advantage of reasonable price and basic working functions, this is considered the reason that the 5-function edge banding machine is chosen by many manufacturers.

2. 7 function edge banding machine MF50D

This is considered an upgrade of the 5-function machine, it increased the durability and life of the 7-function machine compared to 5 function machine.

Should the straight edge banding machine and the inclined edge banding machine be combined?

The perfect combination of straight edge banding machine and inclined edge banding machine. With the inclined edge banding machine you will save a lot of production time. The new innovation in this edge banding machine is to switch between straight and inclined gluing at the push of a button, a complete improvement over previous models, which required complicated and time-consuming mechanical alignment.

The secret to using a durable and highly effective wood edge glue machine

According to experts, 80% of automatic edge banding machine related problems are caused by poor cleaning. Clean the machine regularly with simple operations:

- Regularly clean the glue pot, clean it if the glue sticks to the pot wall or spills out. After each use of the machine, it is necessary to pay attention to clean the machine and the work area clean such as: spray dust, thread, check the vacuum bag, fasten the dust pipe.

- After each working day, it is recommended to check the machinery equipment including the sprocket, bearings, dust collection system, compression system. Oil should be applied to the compressed air system, bearings … to make the machine operate more smoothly and efficiently.

- Lubrication: Lubrication helps reduce friction for parts such as sprockets, rails, bearings, pneumatic systems, etc. to help them work better. This is very important, but in practice we often overlook or ignore it. Therefore, some edge banding machines have an automatic lubrication system available.

- Dewatering in the air compressor: An important note in using compressed air for the edge banding machine is the need to effectively separate the condensate in the compressed air (water mixed in the compressed air will quickly oxidize the details), Sufficient lubricating oil for the compressed air system.

- Selecting the type of glue is also a fairly common mistake. Each glue has a different viscosity and operating temperature. Glue temperature: Should be adjusted according to the glue manufacturer’s recommendations, the principle is that the glue pot temperature is always lower than the roller temperature to avoid the candy being overheated to create a hard dry layer on the surface of the glue pot. Check regularly for layers of glue adhered to the pot walls and details. We should clean the glue pot right after every working day.

Where should I buy a reputable, good price wood edge gluing machine?

Jaya International Co., Ltd is proud to be a reputable supplier of edge banding machines and woodworking machines across the world. We always offer a wide range of genuine edge banding and woodworking machines at competitive prices.

Genuine imported goods with original machine

Make the selection within the planned budget

Nationwide machine warranty 24/7

There are full invoices for customers

Suitable for the working needs of the carpentry industry.

Contact for Consulting and Ordering: