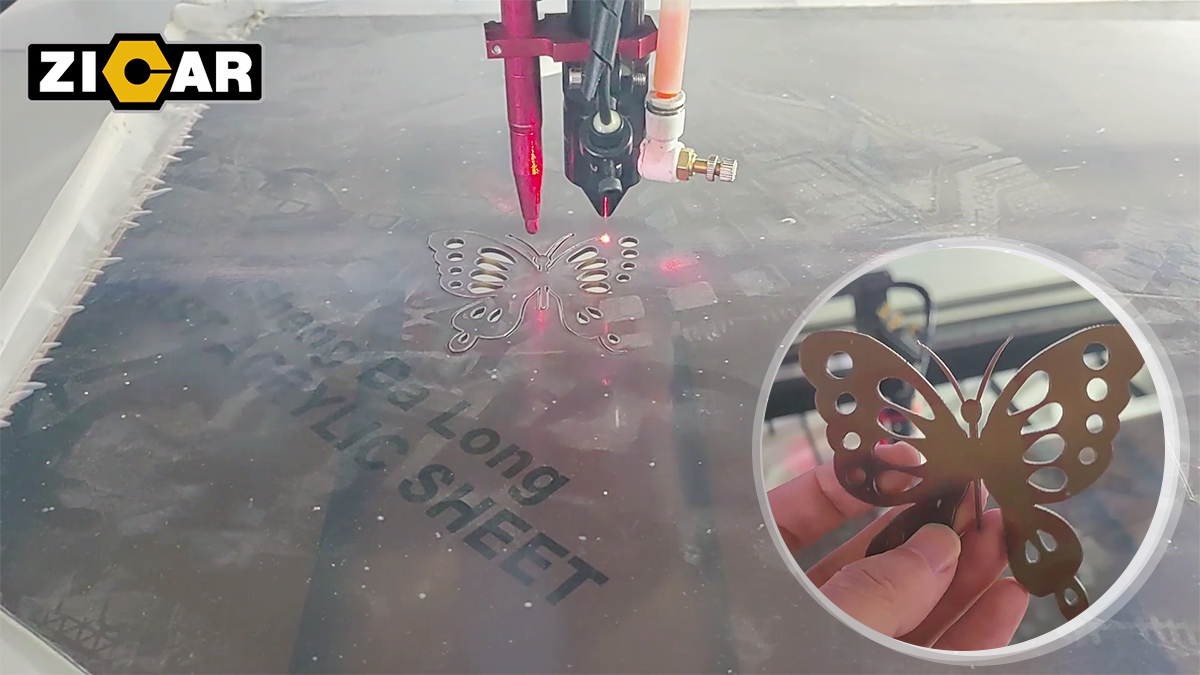

Conventional methods for cutting acrylic involve drills, saws, etc., which is great for small output. For major businesses that need to produce a large amount of products, laser cutting acrylic requires special machines. Laser machine cutting acrylic requires rounded edges, smooth surfaces and more detailed designs.

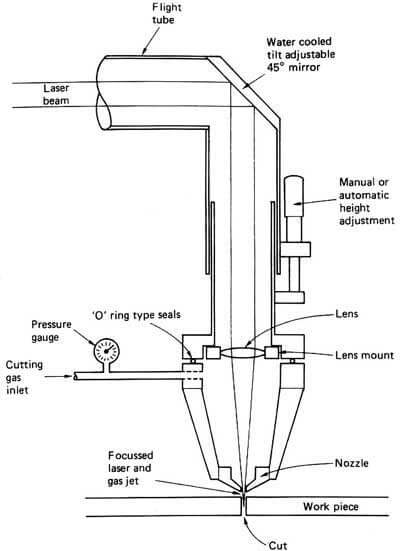

Laser-cut acrylic offers a sleek, high-quality look that appeals to customers. If you want to create smooth, durable pieces, then laser cutting is the best option. Many businesses choose this technology because it creates better products. The laser cutting system uses a high-powered beam of light to heat the material and evaporate it.

Advantages and Disadvantages of Laser Cutting Acrylic

Laser cutting acrylic is rising in popularity, with many factors contributing to its increasing success. It has become an increasingly favored method.

The speed is fast, and it provides high throughput as well as productivity.

You can use it for different applications.

Laser cutting process is relatively safe than conventional cutting methods.

Ordinarily, the latest acrylic laser cutting machines integrate advanced technical features that enhance optimum cutting precision. At the end of the process, you’ll have a perfect laser cut with sharp and edges that won’t fray.