The rip fence and its use in the context of a band saw, which is a woodworking tool used for making straight cuts in various materials, particularly wood.

Let me break down the key points:

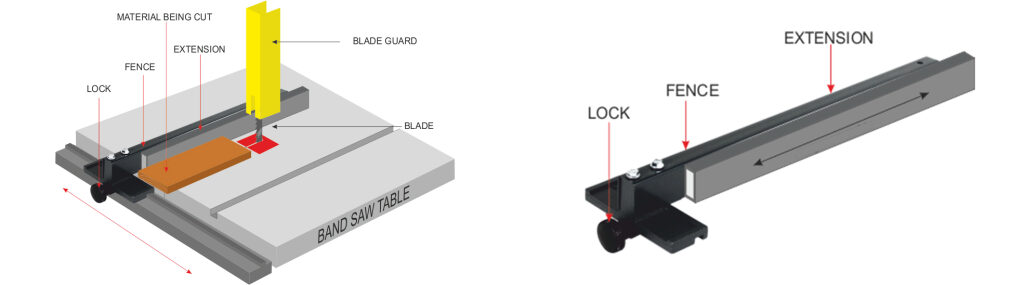

Purpose of the Rip Fence:

The rip fence is a crucial accessory used in woodworking, especially when you need to make straight cuts or rip cuts. Rip cuts are cuts made parallel to the grain of the wood, and they are typically used for creating long, straight pieces of material.

Extension Capability:

Some rip fences can be extended, which means you can adjust their position to accommodate longer pieces of material. This feature is valuable when you need to cut large or lengthy workpieces accurately.

Movement and Locking:

The rip fence can slide horizontally along the table of the band saw, from left to right. This allows you to position the fence at the desired distance from the blade, which determines the width of the material you’ll be cutting. Once you’ve set the fence at the desired position, it can be locked in place to ensure it doesn’t move during the cutting process. Locking the fence helps maintain the accuracy and consistency of your cuts.

Versatility:

A high-quality band saw often comes with a rip fence that can be installed on both the right and left sides of the saw blade. This versatility is useful for various cutting tasks, as it allows you to choose the most suitable side of the blade for your specific project or material.

In summary, the rip fence is an essential accessory for a band saw that helps you make precise and straight cuts. It can be adjusted for different material widths, extended for longer workpieces, and locked in position to ensure accuracy. The ability to install the fence on both sides of the blade enhances the band saw’s versatility.

The distance at which you install and use a rip fence on a band saw depends on the specific woodworking project and the desired width of the cut you need to make. There are no fixed, universal distances for installing and using a rip fence because it can vary depending on your material and your intended cut.

When using a rip fence on a band saw or any woodworking tool, it’s important to set the distance or gap between the rip fence and the saw blade correctly. The distance is determined by the specific material you’re cutting and the type of cut you want to make. Here are some general guidelines for setting the distance:

For Rip Cuts:

When making a rip cut (a cut parallel to the edge of the material), you typically want to set the rip fence so that it’s a small but safe distance away from the blade. A common recommendation is to set the rip fence to be 1/16 to 1/8 inch (1.5 to 3 mm) away from the blade. This small gap prevents the material from binding against the blade while still maintaining accuracy.

For Resawing:

If you’re using the band saw for resawing (cutting thicker pieces into thinner ones), you may need to adjust the distance between the rip fence and the blade based on the thickness of the material. This distance can vary but is often set to match the thickness of the material you want to cut.

Safety Considerations:

Always prioritize safety when using a rip fence. Ensure that the material is properly supported on the table and that the fence is securely locked in place. Never set the fence too close to the blade, as this can lead to dangerous kickback or binding of the material.

Now, if considering to buy a sliding table saw instead of a band saw with a rip fence, here are some points you can consider:

Versatility:

Sliding table saws are known for their versatility. They can handle a wide range of cutting tasks, including crosscuts, miter cuts, and rip cuts, with precision. This versatility makes them suitable for a variety of woodworking projects.

Ease of Use:

Sliding table saws often come with features like precise fence systems and adjustable sliding tables that make it easier to set up and execute accurate cuts. They are user-friendly, especially for those new to woodworking.

Safety Features:

Sliding table saws typically have advanced safety features, such as blade guards, riving knives, and anti-kickback mechanisms, which can enhance safety during operation.

Efficiency:

Sliding table saws can save time and effort compared to using a band saw with a rip fence because they are designed for efficient and precise cutting, reducing the need for additional setup and adjustments.

Professional Results:

If you are serious about woodworking and want to achieve professional-level results, a sliding table saw may be a better choice due to its precision and versatility.

Consider Space:

Keep in mind that sliding table saws are larger and require more workshop space than band saws. Ensure that you have enough room for the saw and the materials they plan to work with.

In summary, a sliding table saw can offer greater versatility, ease of use, safety features, and efficiency compared to a band saw with a rip fence. Depending on your woodworking needs and budget, these advantages may make a sliding table saw a more appealing choice for their workshop.