In the world of furniture manufacturing, technological advancements have revolutionized the industry, paving the way for efficient and precise production. Machines have become an integral part of the process, enabling the creation of stunning designs and high-quality furniture pieces. This article explores the role of key machines, such as CNC router machines, cold presses, drills, and saws, in the furniture manufacturing industry.

CNC Router Machines:

CNC (Computer Numerical Control) router machines have transformed the way furniture is made. These machines utilize computer-controlled movements to cut, shape, and carve various materials, such as wood, plastic, and metal, with unparalleled precision. With their ability to execute complex designs and repetitive tasks effortlessly, CNC router machines have become a go-to solution for furniture manufacturers.

These machines excel at producing intricate details, intricate joinery, and curved edges, enabling furniture makers to create unique and visually appealing designs. Additionally, CNC router machines offer increased efficiency by minimizing waste material and maximizing productivity. They have significantly reduced production time, allowing manufacturers to meet tight deadlines and customer demands effectively.

Cold Presses:

Cold presses are indispensable machines in furniture manufacturing, particularly when it comes to woodwork. These machines apply pressure to join materials together using glue or adhesives, ensuring a strong bond. Cold pressing eliminates the need for high temperatures, which can be detrimental to certain materials and can cause warping or other forms of damage.

Cold presses are used extensively in the production of panel-based furniture, such as cabinets, tables, and bookshelves. They provide uniform pressure distribution, resulting in seamless joints and sturdy constructions. The ability to control pressure and maintain consistent quality makes cold presses an essential tool for achieving durable and aesthetically pleasing furniture pieces.

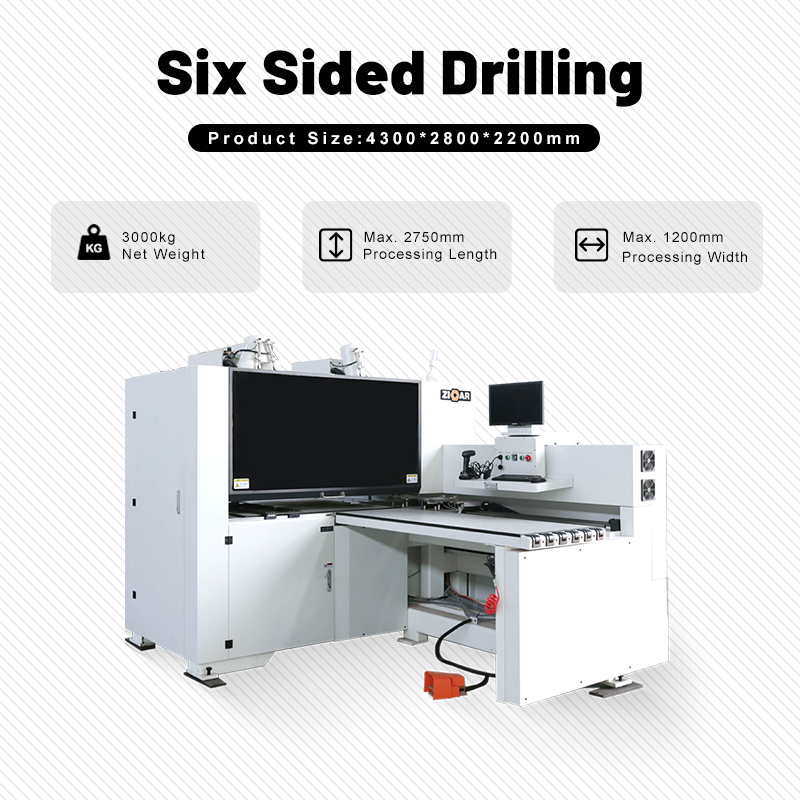

Drills:

Drills play a critical role in furniture manufacturing, enabling the creation of holes, joinery, and assembly points. These machines are employed for various purposes, including attaching hardware, inserting dowels or screws, and shaping components. Drills equipped with precise depth control and adjustable speed settings ensure accuracy in hole placement, allowing for efficient assembly and streamlined production.

Modern drill presses offer enhanced features, such as digital readouts, laser guides, and automatic depth stops, making them indispensable for furniture makers. These machines save time, increase productivity, and improve the overall quality of the final product.

Saws:

Saws are the workhorses of furniture manufacturing, serving multiple functions, including cutting, shaping, and trimming materials.

These machines, coupled with advanced features like laser guides and digital angle displays, empower furniture manufacturers to achieve flawless cuts and perfect dimensions.

The furniture manufacturing industry has embraced the power of machines, transforming the way furniture is made. CNC router machines, cold presses, drills, and saws have revolutionized the production process, enhancing efficiency, precision, and overall quality. As technology continues to advance, these machines will continue to shape the future of furniture manufacturing, enabling the creation of exquisite designs and innovative solutions. Embracing these machines is key to staying competitive and meeting the ever-evolving demands of customers in the dynamic world of furniture production.