Edge banding is the process of covering the exposed sides of wood furniture and giving it a finished look. It is essential for maintaining the durability and sophistication of wood furniture and is commonly used in styles like Nordic and Minimalist. The edge banding not only gives a professional finish but also protects the raw edges from splitting, cracking or warping.

Edge banding is a process that involves applying edging strips to the visible sides of wood furniture, such as desks and bookcases. These strips act to cover up the exposed sides of the materials used in these pieces and prevent the raw surface from causing any damage or scratches by contact with other items. Sometimes, however, the strip may fall off, diminishing the aesthetic appeal of the furniture.

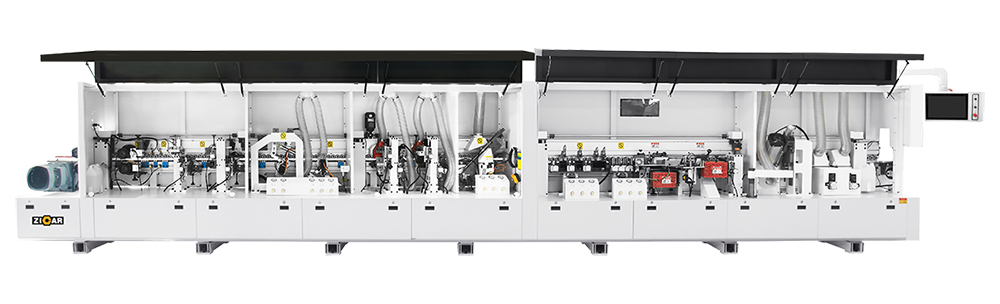

Aiming to optimize the process of wood edge banding,Zicar has recently designed an advanced high-speed edge banding machine that ensures improved quality and appearance of the resulting bandings. This machine not only minimises any risk of damage during transit and in use, but also provides extra protection against deformation as well as making the edges waterproof.

Edge banding is a process that involves attaching an edging material to the edge of a board. This can be done manually or with an automated machine. Edge banding machines are designed for high speed production, but this particular solution is different as it can accommodate multiple workstations and allows for manual configuration, which dramatically increases the efficiency of the change-over and tuning processes.

The benefits of Zicar’s high-speed edge banding machine include:

- One-stop solution to effectively enhance the stability of the production process and product quality. Plus, the warranty liabilities are relatively simple.

- User-friendly operation interface for a more flexible production process adjustment

With the easy-to-use interface, users can adjust workstation configuration at any time. The machine also allows manual adjustment, enabling it to fit any specific processing requirements with shorter tuning time. Moreover, cloning is supported to quickly copy the machine for fast implementation and high working efficiency.

Edge banding is one of the woodworking processes often used to improve the look and feel of furniture pieces. Zicar’s high-speed edge banding machine makes this process more efficient while also making the furnishings more durable and safe. The machine greatly enhances our appreciation of the extraordinary craftsmanship that goes into making a piece of wooden furniture.