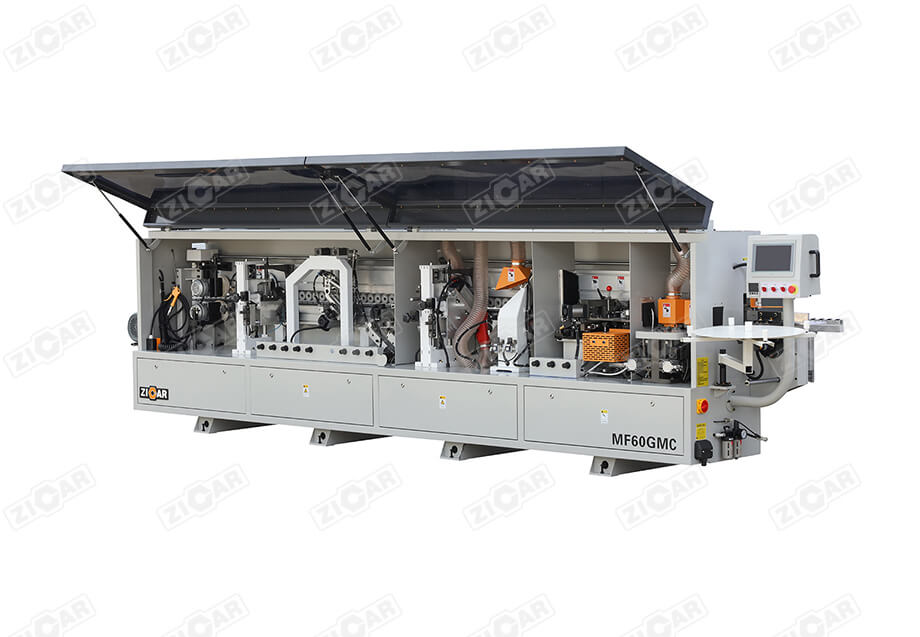

- Optimum quality, made byZICAR

- Latest technology, for thecomplete processing options and a perfect finish

- Intuitive operation via SYNTECcontrol system

- Equipped with 12KW spindle, with large output torque 10NM and high speed.

- Premium machines for premium requirements

- Equipped with 8-station automatic tool magazine and automatic tool setting instrument, it realizes the one-key operation of changing tools.

- Adopt first-line brand parts with stable quality, whichminimizes the equipment failure rates.

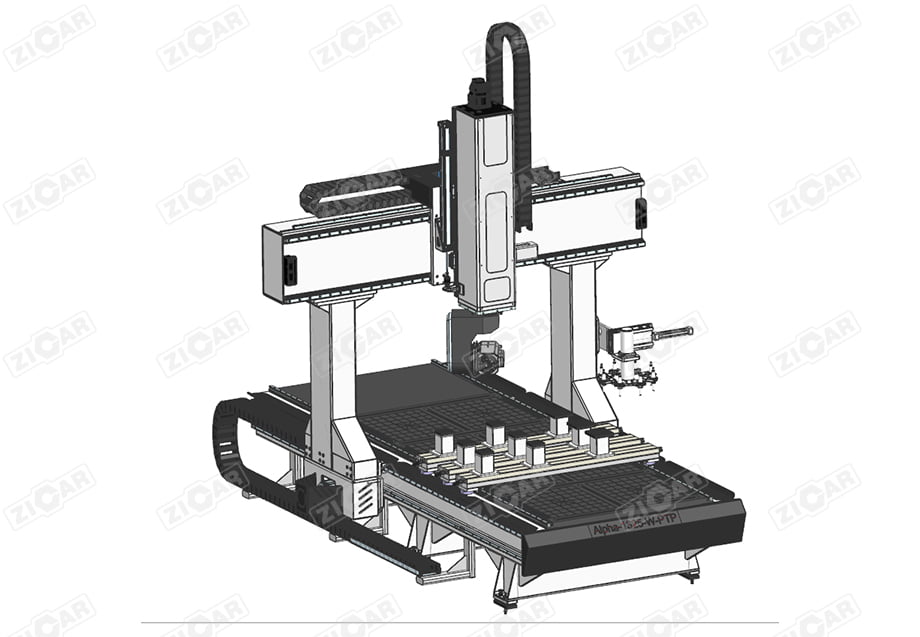

Five axis working center ALPHA 5A SYNTEC control system

SYNTEC control system

Equipped with bus absolute servo motors with five-axis linkage CNC system, open RTCP function, greatly reducing the operation and programming difficulty.

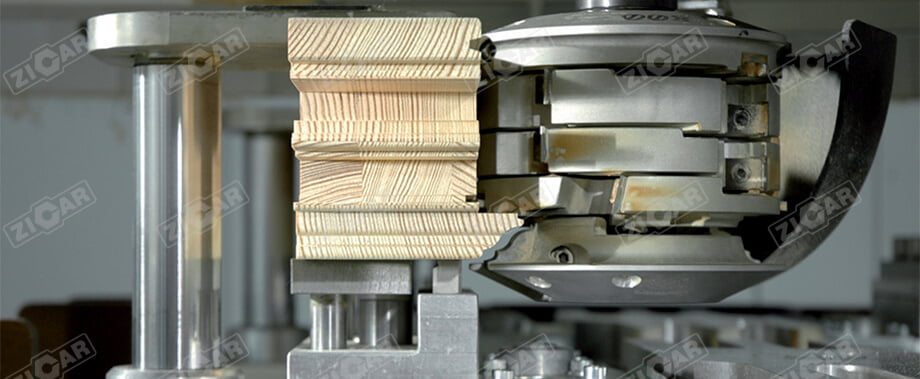

Five axis working center ALPHA 5A Single electric spindle – HITECO

Single electric spindle – HITECO

A single-arm rigid and compact fork houses 10KW electric spindle. Ideal for machining operations that requires minimum overall dimensions such as, for example, machining of moulds or machining plastic materials, complex bended cabinets etc.

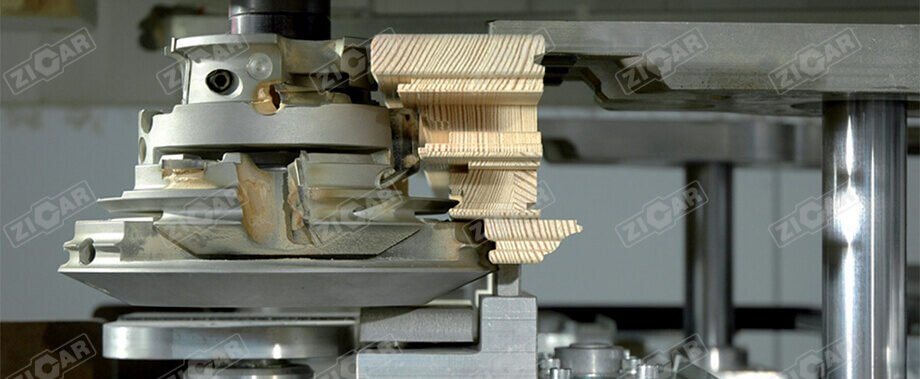

Five axis working center ALPHA 5A Automatic tools changer magazine

Automatic tools changer magazine

8 positions tool changer magazine provides with all operating units equipped with a tool changing spindle (HSK 63F). Rotation is controlled by a servomotor to guaranty maximum positioning precision during tool change.

Five axis working center ALPHA 5A Special designed worktable

Special designed worktable

Supporting the direct adsorption of large plate, T-slot platen, and PTP adsorption blocks platen, which can maximize the compatibility of various machining conditions.