These machines are designed for the construction machinery manufacturing industry, particularly in the production of custom furniture, panel furniture, cabinet wardrobes, and office furniture.

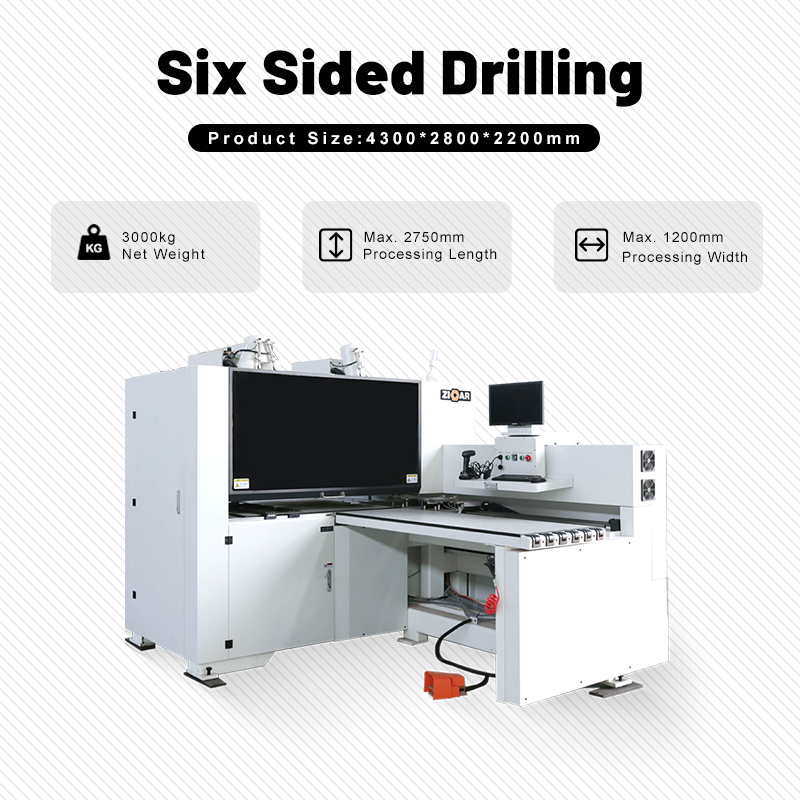

CNC Six-Sided Drilling Machine C6 CNC Six-Sided Drilling Machine C6A

⌈Main Advantages of the C6 Model⌋

Precision and Efficiency:

The C6 machine provides precise and efficient drilling, grooving, and routing on 5 or 6 sides of a panel.

Stability and Accuracy:

An integral frame ensures stable operation, while a patented intelligent three-level lifting gripper improves drilling accuracy, especially for small boards, and avoids surface scratches.

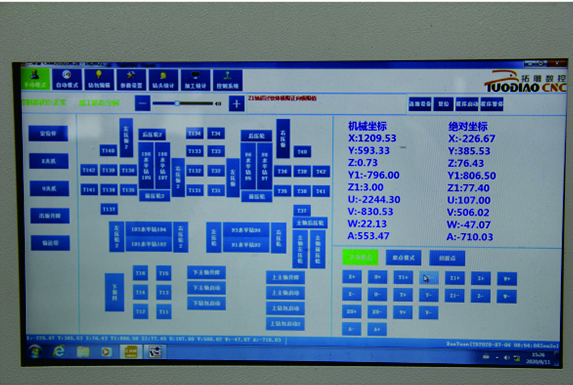

Compatibility with Design Software:

The operating system can handle various file formats without the need for programming, which means direct processing from scanned codes.

Enhanced Processing Efficiency:

A dynamic acceleration algorithm reduces drill bag movement, which in turn improves processing efficiency.

Support for Irregular Shapes:

The machine can process boards of irregular shape, with minimum dimensions being 70mm by 35mm.

Additional Advantages of the C6 Model:

Robust Construction:

The machine features an integral welding steel rack structure with one-piece framework, which ensures stability and precision over its 10-year guaranteed life.

Customized Drill Packages:

The machine boasts exclusive customized drill packages that provide a significant increase in production efficiency, especially with double row drilling.

⌈Advantages of the C6A Model⌋

Comprehensive Functionality:

The C6A model offers six-sided drilling and slotting in one operation, with support for various board sizes and compatibility with different design software.

Robust and Precise Design:

Similar to the C6, it also features an integral welding steel rack structure and a patented three-stage intelligent lifting grip that enhances the precision and stability of operations.

Customized Operation System:

The C6A machine uses a customized operation system with advanced algorithms for dynamic acceleration and slotting speed, improving efficiency and adaptability for shaped plates.

Technical Specifications of the C6A Model:

Versatile Handling:

The C6A can handle panel lengths from 70 to 2800mm, widths from 35 to 1200mm, and thicknesses from 12 to 50mm.

High-Speed Operations:

It operates at a maximum speed of 130m/min, with various drilling components that cater to extensive production needs.

These CNC machines are engineered to streamline production processes, offering high-speed operations and the versatility needed for modern, customized furniture manufacturing. With their robust construction and advanced technological features, ZICAR’s CNC machines present a compelling option for businesses looking to enhance their production capabilities.

ZICAR’s CNC six-sided drilling machines, such as the C6 and C6A models, offer several user benefits on productivity, cost savings, and versatility:

Productivity:

Efficient Operations:

The machines are designed to perform complex drilling tasks quickly and efficiently, handling multiple processes like drilling on 5 or 6 sides, grooving, and routing operations.

Speed:

With high maximum speeds and the capability to perform double row drilling efficiently, these machines can significantly increase production rates, boasting up to a 30%-45% increase in production efficiency.

Automation:

Their compatibility with various design software allows for automation in processing, reducing the time needed for programming and enabling direct processing from scanned codes.

Cost Savings:

Durability:

The integral welding steel rack structure and annealing process to eliminate stress ensure a long lifespan of the machinery, guaranteeing a rack life of 10 years, which can mean lower replacement costs and maintenance over time.

Reduction in Manual Labor:

The exclusive dynamic acceleration and slotting adaptive speed algorithms streamline operations, potentially reducing the need for manual adjustments and intervention.

Versatility:

Support for Various Shapes and Sizes:

The machines can handle irregularly shaped boards, with minimum board sizes supported at 70mm by 35mm for the C6 and 35x70mm for the C6A, broadening the range of products that can be manufactured.

Adaptability:

The air flotation workbench and adaptive gripper functions of the C6A model allow for careful handling of different board types without causing damage, ensuring precision and quality in the final product.

These benefits collectively enhance the manufacturing capabilities of users, allowing them to produce a wider range of products with greater efficiency and at a reduced cost, ultimately leading to an increase in profitability and competitive advantage in the market.

ZICAR’s CNC six-sided drilling machines represent the pinnacle of precision and efficiency in the woodworking machinery industry. With advanced features tailored for custom furniture and cabinetry production, these machines offer unparalleled productivity, substantial cost savings through durable design and automation, and remarkable versatility to handle a diverse range of materials and shapes. Businesses seeking to elevate their manufacturing processes will find ZICAR’s technology an invaluable asset.

Are you ready to transform your production line with cutting-edge precision and efficiency? Contact ZICAR today to discover more about our CNC six-sided drilling machines or schedule a live demo and see the difference in action. Enhance your capabilities, reduce costs, and stay ahead of the competition with ZICAR.